Tulane engineering students place first in design competition

When four biomedical engineering students from Tulane University were chosen for an internship at the Southeast Louisiana Veterans Health Care System (SLVHCS) last summer, they were tasked with identifying an unmet clinical need – something that would not only save money for the agency but improve patient care and satisfaction.

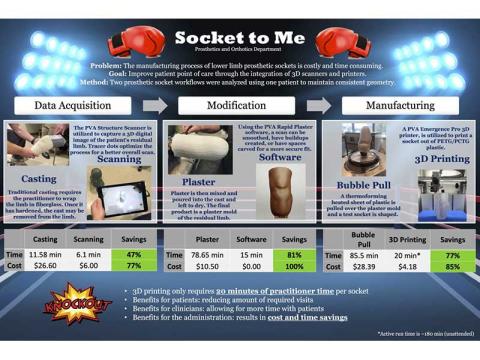

They brainstormed multiple ideas, ultimately settling on a project they dubbed “Socket To Me” — improving the costly and time-consuming process of manufacturing lower limb prosthetic sockets.

With a grant from the National Institutes of Health, they spent the summer transforming their idea into an actual design — a winning design.

At the SLVHCS’s recent Performance Excellence Fair, the team of Kali Dancisak, Carly Harad, Ava Heller and Marjie Williams, won first place out of more than 40 department entries. Judging was based on such factors as patient outcomes and satisfaction, cost-effectiveness, increased workforce efficiency and engagement.

The recognition came with a trophy and a $10,000 prize, which through the Orthotics and Prosthetics Department at the SLVHCS will be used to further develop the design.

“We are ecstatic that our project was awarded first place,” Harad said. “We are proud of our accomplishments, particularly the positive impacts we have had on the veterans and the clinicians providing care.”

Under the guidance of the SLVHCS’s Brian Layman, the team spent the summer of 2020 working alongside prosthetists, orthotists and physical therapists as part of a collaboration with Tulane’s biomedical engineering department.

“Every summer we have a new group of BME students participate in our summer program to help them understand some of the obstacles when designing custom orthotic and prosthetic devices,” said Layman, a certified prosthetist/orthotist with expertise in 3D printing prosthetics. “Understanding patients’ needs and limitations are always unique to the patient, which make designing custom devices challenging and rewarding.”

The Tulane project aimed to assess the potential cost and efficiency benefits of digitizing the prosthetic socket workflow by integrating 3D scanners, 3D printers, and CAD (computer-aided design) software. “To achieve this, we conducted a case study with the goal of improving patient point of care, determined by increasing time efficiency and decreasing costs,” Heller said.

Using both manual and digital methods, they fabricated below-knee prosthetic check sockets, a critical component that serves as an interface between a patient’s residual limb and the prosthetic device. It is also the preliminary step used to perform an initial assessment before the final socket is manufactured.

The students compared the manual and digital processes and concluded that the digitizing below-knee prosthetic check sockets saved time and money.

“This means that they (clinicians) can manufacture multiple sockets at once and spend more time with patients,” said Williams.

The team said further studies would be necessary to validate the results and assess the long-term cost savings. “In the future, we hope to calculate the number of patients that need to be treated in this fashion for the savings effect to be seen,” Dancisak said.

They will continue to do just that, with the two seniors in the group incorporating what they learned over the summer into their year-long capstone design project. In addition, three of the team members are continuing to work at the SLVHCS to sharpen their skills and prepare for life post-graduation, be it finding a job in the health care industry or working toward their master’s degree in biomedical engineering.

All four agreed that the SLVHCS internship, coupled with their biomedical engineering studies, has been an invaluable part of their Tulane experience.

“I have a strong desire to help others and improve clinical outcomes,” Harad said. “Biomedical engineering allows me to apply my technical knowledge to design and develop innovative products and directly impact patient lives.”

She and her teammates got a taste of that through their work at the VA. “My favorite part of my experience so far is the smile my work brings to patient faces,” Harad said. “I am motivated by the happiness and positive impact my work has directly on patient’s lives.”