Principle of ACOMP: Continuously extract and dilute viscous reactor liquid producing a stream through the detectors so dilute that detector signals are dominated by the properties of single polymers, not their interactions. (ACOMP is a non-chromatographic method). Hence, measurements are not dependent on empirical or inferential models.(US patent 6052184 and US patent 6653150, other patents pending)

Features

- Laboratory based analytical technique to aid in discovery and understanding of kinetics and mechanisms;

- To optimize polymerization reactions, both at the laboratory and plant reactor level;

- Ultimately, to monitor and provide full feedback control for full scale industrial reactors.

- Envisioned as the green technology of the future in the polymer manufacturing industry: Because of potential energy savings, waste reduction, pollution reduction, and overall cost-savings for manufacturers.

Acomp set-up

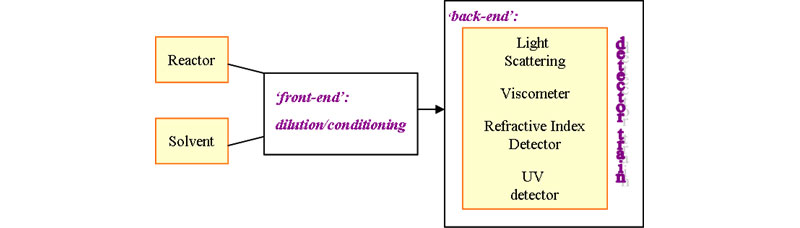

Front end: ensemble of pumps, mixing stages and conditioning elements that ultimately produce the diluted, conditioned stream.

Back end: multi-angle light scattering, differential refractive index detector, UV-visible detector, single-capillary viscometer; infrared, fluorescence and conductivity detectors can be incorporated.

ACOMP (US patent 6052184 and US patent 6653150, other patents pending) measures in a model-independent fashion the evolution of average molar mass and intrinsic viscosity, monomer conversion kinetics and, in the case of copolymers, also the average composition drift and distribution.

Since the sample stream concentrations are in the ideal range of SEC, it is possible to connect an automatic diverter valve and injector loop to the ACOMP sample stream and make periodic, automatic injections into SEC columns interposed between the front-end outlet stream and the detector train.

ACOMP history - as a continuously updated technique

In the beginning…

- Front-end with Shimadzu HPLC pumps and back-end with a 7 angle light scattering unit built by us and Shimadzu UV detectors.

- Our home-built light scattering prototype is now commercialized by Brookhaven Instruments as a modern and powerful light scattering detector (BI-MwA)...

- A more modern version of ACOMP was put together in our labs: flexible front-end (right) and detector train platforms (left)

Now…

- The newest addition is a customized ACOMP platform. Originally built by Polymer Labs under license with Tulane University. It has been heavily modified by Mike Drenski, PolyRMC Associated Director for Instrumentation.

Basic principles of ACOMP

- The monitoring is always adapted to the chemistry. The chemistry is never interfered with or changed to suit the monitoring.

- The quality of data obtained by each instrument is optimized through proper online sample conditioning.

- Measurements are made at the most fundamental level possible (single scattering events, dilute regime viscosity and spectroscopy, etc.) and these are designed to obtain model-free primary quantities. The use of empirical and inferential models and calibration schemes is thereby avoided.

- Obtaining high-quality data with model-free primary quantities allows the richness of the ACOMP results to be used for building chemical, physical and mechanistic models to any degree of elaboration desired, and for potential control of reactions.

Comparing ACOMP with in situ methods (e.g. NIR and Raman)

- Besides conversion, ACOMP additionally monitors the evolution of Mw and [h]w, average polymer properties.

- Raman and NIR can often be put inside the reactor, avoiding ACOMP’s withdrawal, dilution steps and eliminating delay times.

- However, probes inside reactors can easily foul and lead to erroneous data. Working at high concentrations in the reactor normally requires that empirical models and calibrations be used to interpret data, and other phenomena can intervene (e.g. scattering effects of emulsions) that dominate the detector’s response over the desired phenomenon.

- In contrast, the ACOMP ‘front end’ is a flexible platform specifically designed to deal with the conversion of real, often ‘dirty’ and non-ideal reactor contents into a highly conditioned, dilute and continuous sample stream on which absolute, model independent measurements can be made.

Rapidly expanding applications and new frontiers

- Free radical (co)polymerization

- Step growth polymerization

- Controlled radical (co)polymerization (ATRP, NMP, RAFT) and other living types (ROMP)

- Batch, semi-batch continuous, pressurized reactors

- Solvent, bulk, heterogeneous phase, emulsion and inverse emulsion

- Grafting and cross-linking reactions, multiblock syntheses

- Post-polymer modifications; e.g. hydrolysis, quaternization, etc.

- Feedback control, batch, semi-batch, continuous reactors

- On-command polymers

- On the horizon: Extension to slurries, fluidized bed

ACOMP Publications appeared or in press

- F. H. Florenzano; R. Strelitzki; W. F. Reed, “Absolute, Online Monitoring of Polymerization Reactions”, Macromolecules 1998, 31(21), 7226-7238.

- J. L. Brousseau; H. Ç. Giz; W. F. Reed, “Automatic, Simultaneous Determination of Differential Refractive Index of a Polymer and its Corresponding Monomer”, J. App. Pol. Sci. 2000, 77, 3259-3262.

- W. F. Reed, “A Method for Online Determination of Polydispersity during Polymerization Reactions”, Macromolecules 2000, 33, 7165-7172.

- W. F. Reed, “Breaking new ground in polymer science with molecular weight analysis”, invited article, American Laboratory 2000, 32(16), 20-25.

- A. Giz; H. Giz, J. L. Brousseau; A. Alb; W. F. Reed, “Kinetics and Mechanism of Acrylamide Polymerization by Absolute, Online Monitoring of Polymerization Kinetics”, Macromolecules 2001, 34(5), 1180-1191.

- A. Giz; H. Giz; J. L. Brousseau; A. Alb; W. F. Reed, “Online Monitoring of a Stepwise Polymerization Reaction: Polyurethane”, J. App. Polym. Sci. 2001, 82, 2070- 2077.

- B. Grassl; A. Alb; W. F. Reed, “Free radical transfer rate determination using online polymerization monitoring", Macromol. Chem. Phys. 2001, 202(12), 2518-2524.

- B. Grassl; W. F. Reed, “Online polymerization monitoring in a continuous tank reactor”, Macromol. Chem. Phys. 2002, 203, 586-597.

- F. Chauvin; A. M. Alb; D. Bertin; W. F. Reed, “Kinetics and molecular weight evolution during controlled radical polymerization”, Macromol.Chem. Phys. 2002, 203 (14), 2029-2040.

- A. Giz; A. O. Koc; H. Giz; A. Alb; W. F. Reed, “Online monitoring of reactivity ratios, composition, sequence length, and molecular weight distributions during free radical copolymerization”, Macromolecules 2002, 35, 6557- 6571.

- W. F. Reed, “Monitoring Kinetic Processes in Polymer Solutions with Time Dependent Static Light Scattering (TDSLS)”, Ch. 12, pp. 131-151, in Scattering Methods for the Investigation of Polymers, J. Kahovec, Ed., Wiley VCH, 2002.

- W. F. Reed; A. M. Alb; E. Mignard; H. Giz; A. Giz; F. H. Florenzano; R. Farinato “Automatic Continuous Online Monitoring of Polymerization Reactions (ACOMP)”, Polymeric Materials: Science and Engineering 2003, 88, 476-478.

- E. Mignard; O. Guerret; D. Bertin; W. F. Reed, “Automatic Continuous Online Monitoring of Polymerization Reactions (ACOMP) of High Viscosity Reactions”, Polymeric Materials: Science and Engineering 2003, 88, 314-316.

- W. F. Reed, “Automatic, Continuous Mixing Techniques for Online Monitoring of Polymer Reactions and for the Determination of Equilibrium Properties”, ch. 20, pp. 589- 622, Handbook of Size Exclusion Chromatography and Related Techniques", 2nd Ed., Chi-san Wu, Ed., Marcel Dekker, 2003.

- H. Çatalgil-Giz; A. Giz,; A. M. Alb; W. F. Reed, “Absolute Online Monitoring of Acrylic acid Polymerization and the Effect of Salt and pH on Reaction Kinetics”, J. Appl. Pol. Sci. 2004, 91, 1352-1359.

- D. Sunbul; H. Catalgil-Giz; W. F. Reed; A. Giz, “An error in variables method for determining the reactivity ratios by on-line monitoring of copolymerization reactions”, Macromolecular Theory and Simulation 2004, 13, 162-168.

- E. Mignard, T. Leblanc, D. Bertin, O. Guerret, W. F. Reed , “Online monitoring of controlled radical polymerization : Nitroxide mediated gradient copolymerization”, Macromolecules 2004, 37, 966-975.

- W. F. Reed, “Automatic Continuous Online Monitoring of Polymerization reactions (ACOMP)”, Feature Article, Polymer News 2004, 29, 271-279.

- F. H. Florenzano; V. Fleming; P. Enohnyaket; W. F. Reed, “Coupling of Near Infra-Red spectroscopy to Automatic Continuous Online Monitoring of Polymerization Reactions”, European Polymer Journal 2005, 41, 535-545.

- R. S. Farinato; J. Calbick; G. A. Sorci; F. H. Florenzano; W. F. Reed, “Online monitoring of the final divergent growth phase in the stepgrowth polymerization of polyamines”, Macromolecules 2005, 38, 1148-1158.

- E. Mignard; J.-F. Lutz; T. Leblanc; K. Matyjaszewski; O. Guerret; W. F. Reed, “Kinetics and Molar Mass Evolution during Atom Transfer Radical Polymerization of n-Butyl Acrylate Using Automatic Continuous Online Monitoring”, Macromolecules 2005, 38, 9556-9563.

- A. M. Alb; R. Farinato; J. Calbeck; W. F. Reed, “Online monitoring of polymerization reactions in inverse emulsions”, Langmuir 2006, 22, 831-840.

- A. M. Alb; P. Enohnyaket; M. Drenski; A. Head; A. W. Reed; W. F. Reed, “Online monitoring of copolymerization using comonomers of similar spectral characteristics”, Macromolecules 2006, 39, 5705-5713.

- A. M. Alb; P. Enohnyaket; R. Shunmugam; G. N. Tew; W. F. Reed, “Quantitative contrasts in the copolymerization of acrylate and methacrylate monomers”, Macromolecules 2006, 39, 8283-8292.

- M. F. Drenski; E. Mignard ; W. F. Reed, “Direct Measurement of Chain Transfer during Controlled Radical Polymerization”, Macromolecules 2006, 39, 8213-8215.

- A. M. Alb; P. Enohnyaket; J. F. Craymer; T. Eren; E. B. Coughlin, W. F. Reed, “Online monitoring of Ring Opening Metathesis Polymerization of Cyclooctadiene and a Functionalized Norbornene”, Macromolecules 2007, 40, 444-451.

- A. M. Alb; A. Paril; H. Çatalgil-Giz; A. Giz; W. F. Reed , “Evolution of composition, molar mass, and conductivity during the free radical copolymerization of polyelectrolytes”, J. Phys. Chem. B 2007, 111 (29), 8560 -8566.

- A. Paril; A. M. Alb; W. F. Reed, “Online Monitoring of the Evolution of Polyelectrolyte Characteristics during Postpolymerization Modification Processes” Macromolecules 2007, 40, 4409-4413.

- A. M. Alb; M. F. Drenski; W. F. Reed, "Monitoring of Polymerization and other Polymeric Processes in Solution", invited article for Progress in Polymer Science. In press.

- A. M. Alb; M. F. Drenski; W. F. Reed, “ Implications to Industry: Perspective. Automatic continuous online monitoring of polymerization reactions (ACOMP)”, Polymer International 2008, 57, 390-396.

- A. M. Alb; A. K. Serelis; W. F. Reed, “Kinetic trends in RAFT homopolymerization from online monitoring”, Macromolecules 2008, 41(2), 332-338.

- A. M. Alb; W. F. Reed, “Simultaneous Monitoring of polymer and Particle Characteristics during Emulsion Polymerization”, Macromolecules 2008, 41(7); 2406-2414.

- G. Gonzalez Garcia; T. Kreft; A. M. Alb; J. C. de la Cal; J. M. Asua; W. F. Reed, “Monitoring the Synthesis and Properties of Copolymeric Polycations”, J. Phys. Chem. B 2008, Web Release Date: 10-Sep-2008.